The Buzz on Sheroz Earthworks

The Buzz on Sheroz Earthworks

Blog Article

The smart Trick of Sheroz Earthworks That Nobody is Discussing

Table of ContentsThe Buzz on Sheroz EarthworksHow Sheroz Earthworks can Save You Time, Stress, and Money.The Best Strategy To Use For Sheroz EarthworksAn Unbiased View of Sheroz EarthworksThe Buzz on Sheroz EarthworksThe Best Strategy To Use For Sheroz Earthworks

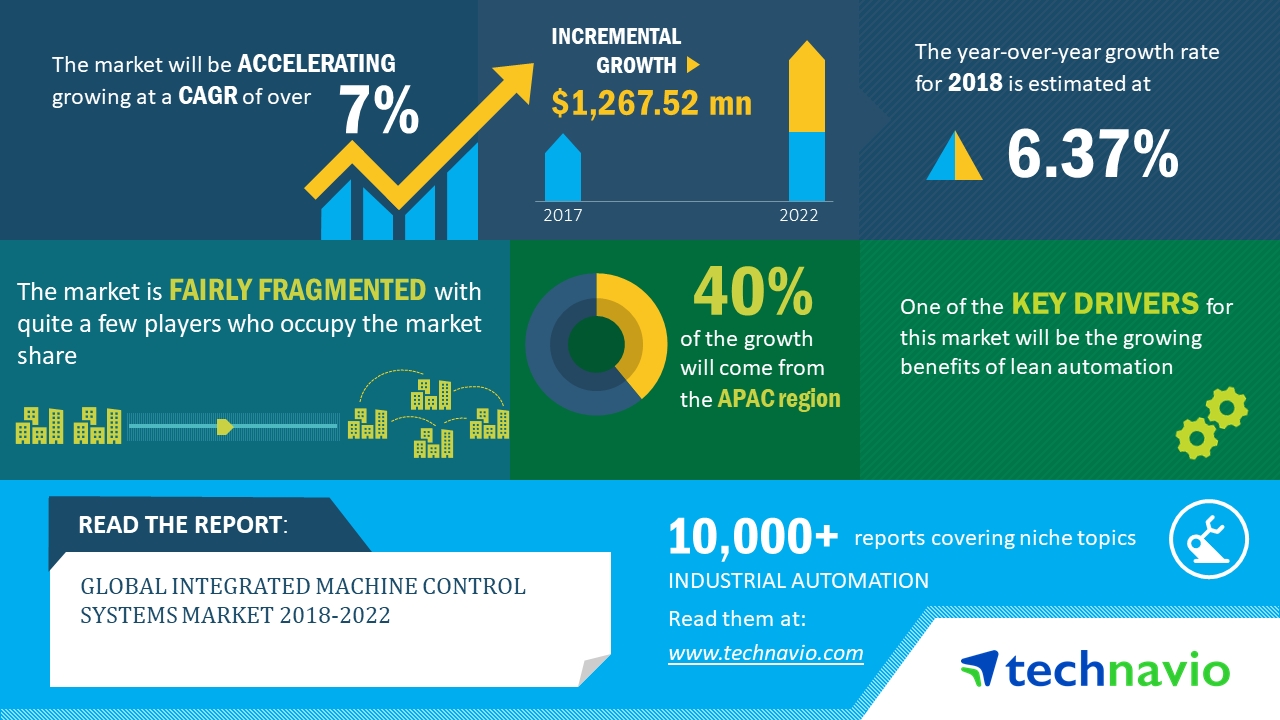

Today, Smart Construction Remote connects over 700 machines on jobsites to workplaces, conserving countless hours formerly spent by jobsite managers, surveyors and designers travelling from workplaces to jobsites. To summarise, the very first 10 years of Komatsu's smart maker control have been noted by a decade of special innovation, continual learning and growth with consumers.

Right here's to the next 10 years! Web content created in association with Komatsu.

In the rapidly advancing world of construction, precision and efficiency are essential. 3D equipment control, a system that utilizes general practitioner and various other sensing units to assist machinery with pinpoint precision, is revolutionising the sector - https://qualtricsxmkpyy9kbs2.qualtrics.com/jfe/form/SV_3IOcfD5rXwnI6x0. From its very early days of 2D assistance, this innovation has actually advanced significantly, making jobs that as soon as required hands-on treatment currently possible with marginal human input

In construction, it makes certain that every cut, fill, and grade is implemented with surgical precision. Let's explore exactly how this game-changing innovation works. At the core of any type of 3D maker control system are GNSS receivers and antennas, recording satellite signals to establish the machine's precise place. Onboard computers and control boxes process this information and interact with the machinery.

About Sheroz Earthworks

This includes establishing up GNSS receivers, calibrating sensing units, and configuring the equipment control software program - topcon laser levels. The magic of 3D machine control exists in its real-time data collection and processing.

Customer user interfaces offer real-time updates on the equipment's setting and necessary modifications, making certain accurate control. In building and construction, 3D machine control is utilized for earthmoving, grading, paving, and excavation, making certain tasks are finished to exact requirements.

The 7-Second Trick For Sheroz Earthworks

3D machine control considerably enhances performance by reducing rework and minimising material waste, resulting in quicker and much more affordable task conclusion. The modern technology makes certain every job is implemented specifically as prepared, leading to constantly high-grade job. Among one of the most engaging advantages of 3D equipment control is the substantial cost financial savings it offers.

Gas usage is optimised due to the fact that machines run much more successfully and stay clear of unneeded movements. By lowering human mistake and restricting exposure to harmful environments, 3D device control boosts worker safety and security and decreases crashes.

From building to mining, this technology ensures jobs are performed properly and safely, decreasing prices and improving results. As advancements proceed, the possibility for 3D device control to better improve performance and safety grows. Welcoming this technology is necessary for industry specialists seeking to remain competitive and achieve the highest possible standards in their jobs.

Sheroz Earthworks Fundamentals Explained

Discover the future of precision and efficiency currently! Inspect out our newest YouTube video clip on the FJD H36 Electric Motor Grader Control System to see the technology in action: View now.

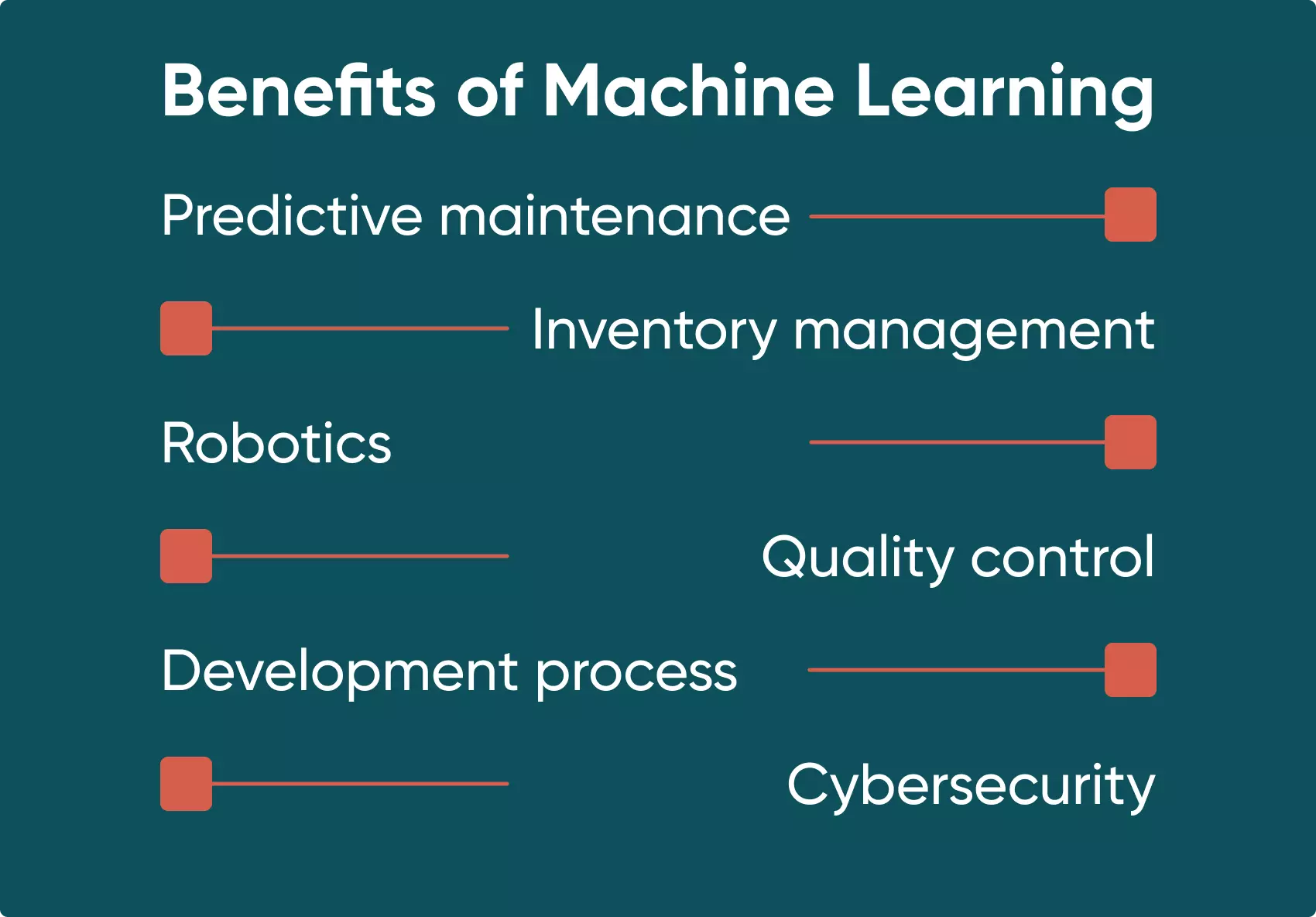

Throughout the years, we have actually seen drivers with great deals of experience do some remarkable points with their equipments. Perhaps they have an eye for adjustments that boost precision, or possibly they understand which attributes of their equipment to utilize and when to enhance productivity or efficiency - https://writeablog.net/sherozau/sheroz-earthworks-pty-ltd-and-sheroz-hire-pty-ltd-est. But with today's developments in hefty tools innovation, even skilled operators can gain from a real-time aid to boost their daily performance (trimble repair parts).

This is where Discover More device control systems factor in. Some excavators come with machine control systems that guide the operator with features to automate the excavating procedure.

All about Sheroz Earthworks

With this included accuracy, rework is virtually eliminated, allowing the driver to finish the task promptly and relocate to the next task. For those dealing with hazardous or tough jobsites, remote-controlled services open new opportunities. This impressive add-on permits you to operate an excavator from a range in locations with dangerous materials (like in a potash mine) or bad ground problems (like mud).

Equipment control systems offer valuable advantages to greater than just excavator drivers. On-board weighing apps for wheel loaders, for example, are preferred since many are so very easy to use. On-board evaluating makes quick job of exact filling. If you have a vehicle come in with a target of 23 lots, your driver can fill their pail and dynamically weigh itoften without even being fixed.

This suggests the operator can see the precise weight of the lots they're concerning to discard (fj dynamics autosteer review). On-board weighing supplies real-time insight into the container's tons to make overloading, underloading, reweighing and waiting times a point of the past. Volvo Building and construction EquipmentIf they unload 12 lots on the initial pass, the next pail requires to weigh 11 lots

Little Known Facts About Sheroz Earthworks.

A lot of procedures make use of an on-board considering application to make sure that the lots is accurate before they send their trucks to the ranges, which is important since the scale weight is what's used for billing and invoicing functions. A number of producers consist of some kind of considering program on their loaders. Some likewise have features that enable business to keep track of and manage the overall tons of numerous trucks.

Report this page